Phenolic Pultured Gratings

US Coast Guard approved Phenolic gratings is an alternative to maintenance-intensive steel gratings for applications where conventional gratings cannot be used. Phenolic grating can withstand high temperatures and direct flame while maintaining its structural integrity. The feature makes the grating ideal for a wide range of offshore, marine, transportation and industrial applications. Fibergrate’s flame resistant phenolic pultruded grating is US Coast Guard approved for Level 2 performance criteria.

Advantages

• High Flame Resistant

• Low Smoke and Toxic Fume Emissions

• High Temperature Resistance

• Corrosion Resistant

• Low Maintenance

• US CG PFM 2-98 Level 2 Approved

Certificates

US CG, ASTME 84-12 , SGS Test Certificate,

ABS Type Approval Certificates.

| UNIFORM LOAD TABLE - Deflection in Millimeters | ||||||||||||

| Clear Span (mm) | Style | UNIFORM LOAD = kN/m2 |

Max Rec Load (kN/m2) |

Ultimate Load (kN/m2) |

||||||||

| 3 | 5 | 10 | 15 | 20 | 30 | 50 | 75 | 100 | ||||

| 400 | l6015 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | 0.4 | 0.5 | 328 | 657 |

| l4015 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | 0.4 | 492 | 985 | |

| 600 | l6015 | <0.3 | <0.3 | 0.4 | 0.6 | 0.7 | 1.1 | 1.8 | 2.7 | 3.6 | 179 | 358 |

| l4015 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | 0.4 | 0.6 | 0.9 | 1.2 | 268 | 537 | |

| 800 | l6015 | 0.4 | 0.7 | 1.3 | 1.9 | 2.6 | 3.9 | 6.5 | 9.7 | --- | 110 | 220 |

| l4015 | <0.3 | 0.4 | 0.8 | 1.2 | 1.6 | 2.5 | 4.1 | 6.1 | 8.1 | 165 | 331 | |

| 1000 | l6015 | 0.9 | 1.5 | 3.0 | 4.6 | 6.1 | 9.1 | --- | --- | --- | 81 | 162 |

| l4015 | 0.6 | 1.0 | 2.1 | 3.2 | 4.2 | 6.4 | 10.6 | --- | --- | 122 | 244 | |

| 1200 | l6015 | 1.8 | 3.0 | 6.0 | 9.0 | 12.0 | --- | --- | --- | --- | 65 | 131 |

| l4015 | 1.2 | 2.0 | 4.0 | 6.0 | 8.1 | 1.21 | --- | --- | --- | 98 | 196 | |

| CONCENTRATED LINE LOAD TABLE - Deflection in Millimeters | ||||||||||||

| Clear Span (mm) | Style | LINE LOAD = kN per m of Panel Width (kN/m of width) |

Max Rec Load (kN/m) |

Ultimate Load (kN/m) |

||||||||

| 0.7 | 1.5 | 3.0 | 5.0 | 10.0 | 15.0 | 20.0 | 25.0 | 30.0 | ||||

| 400 | l6015 | <0.3 | <0.3 | <0.3 | <0.3 | 0.3 | 0.6 | 0.8 | 1.0 | 1.2 | 63 | 126 |

| l4015 | <0.3 | <0.3 | <0.3 | <0.3 | 0.4 | 0.6 | 0.8 | 1.0 | 1.1 | 95 | 190 | |

| 600 | l6015 | <0.3 | <0.3 | 0.4 | 0.6 | 1.1 | 1.7 | 2.2 | 2.8 | 3.3 | 54 | 108 |

| l4015 | <0.3 | <0.3 | <0.3 | 0.3 | 0.7 | 1.1 | 1.5 | 1.9 | 2.3 | 81 | 163 | |

| 800 | l6015 | <0.3 | 0.4 | 0.8 | 1.3 | 2.5 | 3.8 | 5.1 | 6.3 | 7.6 | 47 | 93 |

| l4015 | <0.3 | <0.3 | 0.5 | 0.8 | 1.7 | 2.5 | 3.4 | 4.2 | 5.1 | 70 | 140 | |

| 1000 | l6015 | 0.3 | 0.7 | 1.4 | 2.3 | 4.7 | 7.1 | 9.5 | 11.9 | --- | 41 | 81 |

| l4015 | <0.3 | 0.4 | 0.9 | 1.6 | 3.2 | 4.7 | 6.3 | 7.9 | 9.5 | 61 | 122 | |

| 1200 | l6015 | 0.5 | 1.1 | 2.3 | 3.9 | 7.9 | 11.9 | --- | --- | --- | 36 | 72 |

| l4015 | 0.4 | 0.8 | 1.6 | 2.6 | 5.3 | 7.9 | 10.6 | --- | --- | 54 | 109 | |

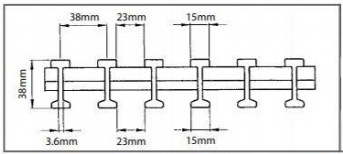

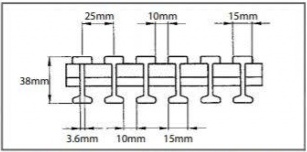

| # of Bars/m of Width | Load Bar Depth | Open Area | Load Bar Centers | Approx. Weight |

# of Bars/m of Width | Load Bar Depth | Open Area | Load Bar Centers | Approx. Weight |

| 26 | 38mm | 60% | 38mm | 13.8 kg/m2 | 39 | 38mm | 40% | 25mm | 20.2 kg/m2 |